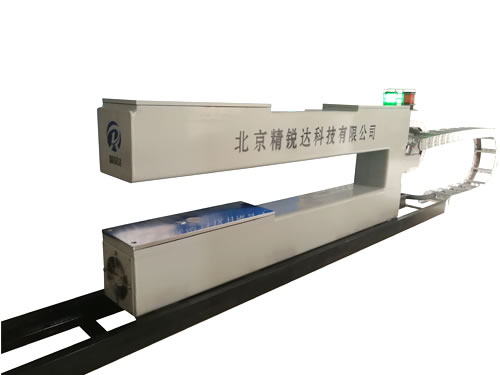

brief introduction:Features of jrd-100kv X-ray thickness gauge: integrated X-ray high voltage source, closed-loop control of current, automatic regulation, stable installation and reliability of ray emission. The thickness change of strip within the range does not need to a

Product features of jrd-100kv & nbsp; X-ray thickness gauge: 1. This model is mainly used for cold rolling single stand reversing mill. 2. The measurement accuracy can reach one thousandth. 3. The integrated X-ray high-voltage source is adopted, the current is controlled in closed loop, automatically adjusted, and the ray emission is stable and reliable. The thickness change of strip within the range does not need to adjust the integrated X-ray high voltage value and current value, and the one-stage control is implemented to achieve the most advanced X-ray measurement and control technology level in the world. The source box of this model can provide air-cooled and water-cooled cooling modes, which can be selected by customers according to the site use requirements. 4. The software interface is intuitive, all Chinese, easy to operate, and can preset a variety of alloy calculation curves. Users can switch flexibly according to the production material. 5. Built in standard sample, automatic calculation of thickness gauge accuracy. 6. Correction prompt function & nbsp; users can set correction prompt according to shift schedule time, once per shift. 7. The data record automatically saves the thickness data, the number of out of tolerance meters, out of tolerance and strip length of each rolling pass, and the storage period is one year. When you need to search, you can search accurately according to the time or directly input the coil number, and print it. 8. Section scanning this function can measure the width of the whole board, save in the way of curve record, and print. 9. Data monitoring & nbsp; real time monitoring and saving of the main parts of the equipment, such as: X-ray source box temperature, detector temperature, detector voltage, thickness voltage. If the thickness gauge fails, you can look at the historical data to analyze the cause. 10. Provide remote assistance. The thickness gauge needs to be connected to the external network. The engineer accesses the software interface of the thickness gauge remotely and judges the problem according to the software analysis to improve the efficiency of problem handling. 11. Adopt TCP / IP communication mode.